Salesforce Field Service is an extension of Service Cloud that provides a comprehensive view of workforce management. Field Service involves providing services to customers beyond our office or site – which is referred to as in the “field”. In simple words, when a customer orders a new product service, the product installer will show up – where they are now, where they’re going, and how many products are in their van – all managed with Field Service Lightning.

Today in this modern world, every company would require some tools to manage the modern Field Service team , warehouses, Vans, Trucks and distribution centers. In order to provide a great Customer Experience, a great Employee experience is also required, which can be easily provided by using tools such as Salesforce Field Service.

Now when we are dealing with products in Salesforce, we need a data model to manage our products while providing services to the customers.

Field Service’s inventory Objects can be used to track the storage, request, transfer, and consumption of every item in the inventory. It also ensures that the mobile workforce has the right parts in stock to do their job. That is , whether the products are consumed to complete a work order, or moved between different field service technicians , or between different locations. All of this can be handled hassle free with SFS Inventory Management.

Before we start, look deeply into the inventory data model. Let’s look at some objects and their purpose in FSL Inventory. These features are available in Salesforce as tabs or related lists:

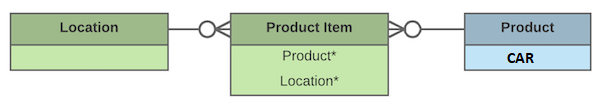

For E.g:- If you have 100 cars stored in Warehouse A and 400 cars stored in Warehouse B. Then, you need to create two product items for these two locations. On inventory location the quantity is updated automatically once the product is transferred to a different location , or the product is consumed, i.e. if it is sold.

For E.g:- If we have 100 cars stored in Warehouse A and 400 cars stored in Warehouse B. Then, we need to create two product items for these two locations. On inventory location the quantity is updated automatically once the product is transferred to a different location , or the product is consumed, i.e. if it is sold.

Product Item 1 - Product - CAR , Location: WAREHOUSE A , Quantity - 100

Product Item 2 - Product - CAR , Location: WAREHOUSE B , Quantity - 400

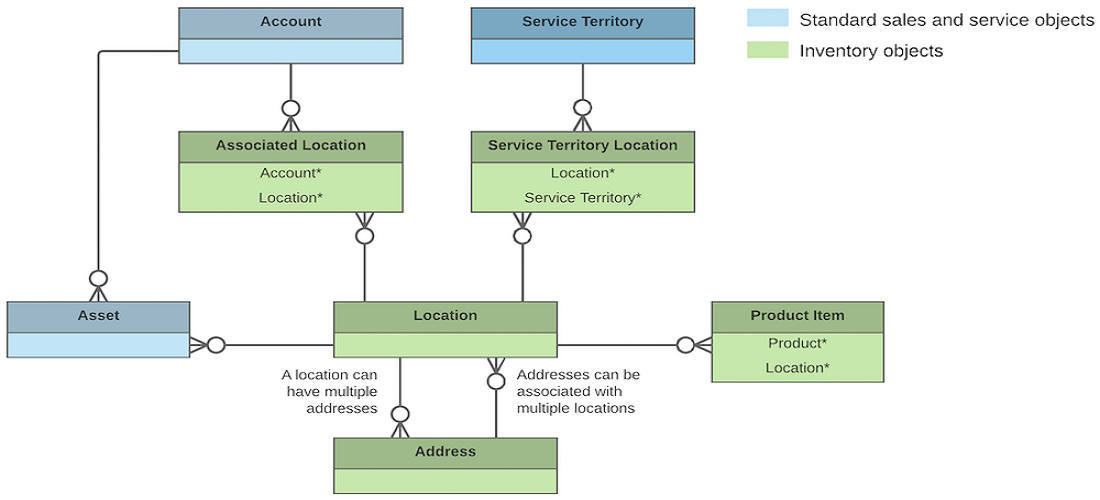

For E.g:- If a location is a Shopping Mall, then all the accounts that work in the shopping mall can be associated with the same location. Associated locations can be created which will be linked to Accounts and location in the system to keep track of Customer sites.

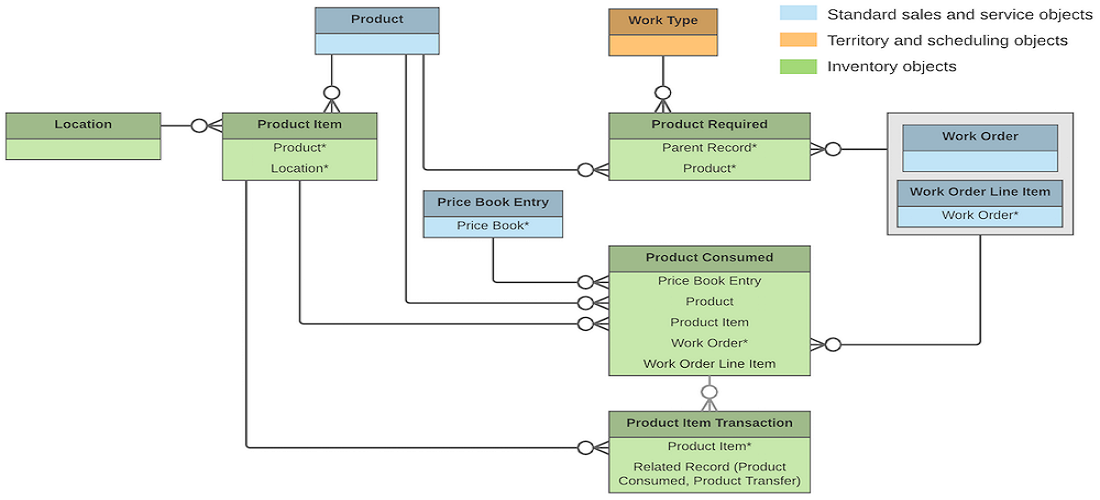

For E.g:- A Car that you have sold to the customer, has got some issue. The customer called the Service center raised a case that the side mirrors of the car are broken due to some storm that happened a few days back in the city. Upon receiving this request the customer service agent would be creating a case, as well as a Work Order by choosing the Work Type. Work Type includes Product Required :- Side Mirrors, Bolts, etc. Now a service appointment etc, is created and this work is assigned to a Field Service Technician.

Now, the technician has got the information from the Work Order about the product required, he would be visiting the customer site prepared.

Now , in order to set up the SFS configuration. Assign user permissions as well update page layouts etc. for usage for users of SFS App.

1- Customize Inventory Settings:

| Users who will: | Need these permissions |

|---|---|

| Enable Field Service | Customize Application |

| View the Locations,Products, Product Items, Product Requests, Product Transfers, Return Orders, or Shipments tab and records | Read on the object |

| Create, edit, or delete locations, products, product items, product requests, product transfers, return orders, or shipments | Create, Edit or Delete on the object |

| Add products required to work orders, work order line items, or work types | Edit or work orders, work order line items, or work types |

| Create, edit or delete products consumed on work orders or work order line items | Create on work orders AND Read on product items |

| View product item transactions | Read on product items |

| Edit product item transactions | Edit on product items |

| Create address for locations | Create on Addresses |

○ Location ○ Address ○ Associated Location ○ Product ○ Product Consumed ○ Product Item ○ Product Item Transaction ○ Product Request ○ Product Request Line Item ○ Product Required ○ Product Transfer ○ Return Order ○ Return Order Line Item ○ Shipment ○ Work Order ○ Work Order Line Item

○ Locations ○ Products ○ Product Items ○ Product Requests ○ Product Request Line Items ○ Product Transfers ○ Return Orders ○ Shipments

2- Create Inventory Locations for Field Service:-

User Permissions

| To create locations: | Create on locations |

|---|---|

| To view associated locations: | Read on accounts |

| To create, update, or delete associated locations: | Edit on accounts |

Create locations so you can track the items stored there and restock when necessary. Creating different locations, specifying if one is an inventory location , etc.This would be used to represent stock/inventory of various products in the system.

3- Create Product Items to Represent Inventory

In order to store 500 cars stored at two different locations (example that I have given above). For that , we would need to create two Locations , two product Items in the system.

1- Common Inventory Management Tasks

There are various tasks which are required to be done in order to manage the inventory in the system.

| Task | Steps to manage |

|---|---|

| Track the quantity of product at a location | Create Product Items to capture this info. |

| Find what is stored at a particular location inventory | Refer to the product Item related list on the Location record. This would show all the products stored at a location. |

| To check the quantity of a product at all the locations | Refer to the related list (Product Item ) on the Product. |

| Review the changes of stock of a particular product at a particular location | Use Product Transaction related list on product items to refer to all these details. |

| To specify that a particular product is needed to complete a work order | Product required related list records can be created on work order for this. |

| Request more products from other inventory when my inventory gets low. | Create product requests when required for the part. |

| Transfer parts between inventory. | Create Product Transfer. Choose the product required , source, destination,etc. Create a shipment to track the information. Mark product transfer complete , when the product is received. |

2- Track Required Inventory

If a work order needs to be completed by an electrician with Voltmeter, then don’t assign it to a carpenter with a saw! Add products required to work types, work orders, and work order line items to ensure that the assigned service resource arrives with the right equipment.

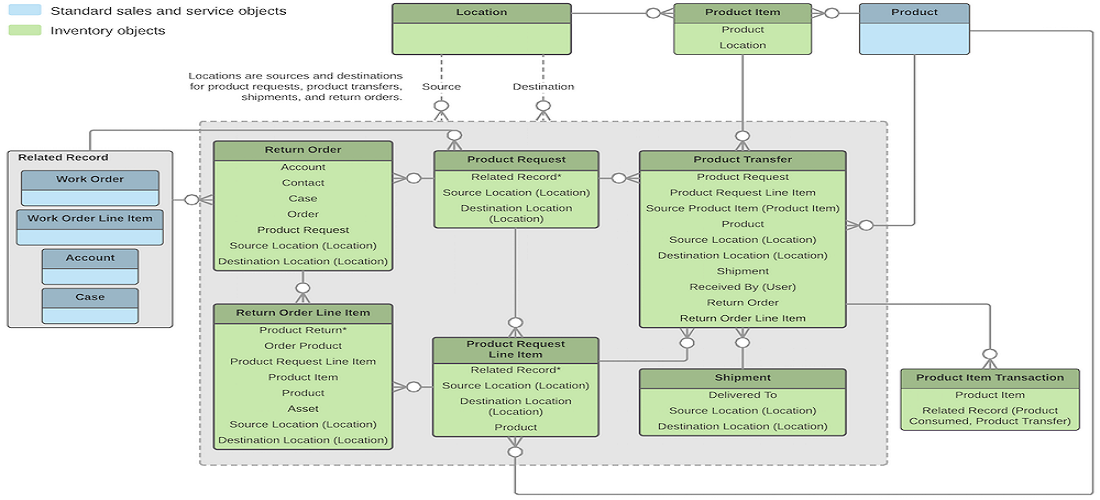

3- Request Inventory

When your stock gets low or you need a part for a particular work order, create a product request. Product requests can be associated with work orders, work order line items, cases, and accounts. You can specify when and where the parts are needed, and divide the request into line items that each represent a needed part.

E.g:- A new request came from one of the clients, who have recently bought SOLAR from ABC Associates. Now, the customer service agent has created a case , which in order created a work order, by using the work type. At this time, the work order should have a list of items which are required to complete the request. Now, if the particular item is not available, then can create a record for Product Request to represent the item needed to complete the request is not available and service resource would need this item.

4- Transfer Inventory

To fulfill a product request, create a product transfer. Product transfers track the movement of inventory from one field service location to another. The inventory numbers at your storage locations update automatically to reflect transfers.

5- Track Inventory Consumption

Create products consumed to track the use or consumption of items from your inventory. As soon as a service appointment is completed. Then some product items would have been consumed. That should be tracked in the system with Products Consumed.

6- Track Inventory Shipments

To track product items while they’re in transit between locations, create shipments. Shipments contain information about the products on board, the shipping carrier, and the expected delivery date.

7- Track Customer Returns

Create return orders to facilitate the return and repair of items that were sold to customers or supplied to field service workers.

You can add up to 5 agencies to your list and contact all of them at once. This will increase your chances of finding the right provider for your needs.